Namco Alloy Steel Plates are crafted to take on the toughest industrial demands—Available in a range of grades & compositions, each plate is alloyed to deliver maximum strength, thermal stability, and corrosion resistance. Backed by expert support and stringent quality control, Namco ensures you get the right plate for the right job. When performance, protection, and durability matter—choose the steel that’s built to rise above every challenge.

Namco Alloy Steel Plates are built to perform where conventional steels fall short. Engineered for extreme environments, they offer outstanding resistance to heat, impact & corrosion—ensuring reliable, long-term performance even under the most demanding industrial conditions.

Built to Handle Harsh Environments

Performs reliably in acidic, corrosive, or moisture-heavy settings with enhanced alloy compositions. Engineered with advanced alloying to withstand abrasion, impact, and aggressive chemical or marine environments.

Built to Handle Harsh Environments

Performs reliably in acidic, corrosive, or moisture-heavy settings with enhanced alloy compositions. Engineered with advanced alloying to withstand abrasion, impact, and aggressive chemical or marine environments.

Delivers high load-bearing capacity and stable performance—even in extreme heat or cryogenic cold. Ideal for industries—where performance under pressure is non-negotiable.

Maintains internal strength and surface integrity through years of heavy-duty use—even under fluctuating or impact-heavy conditions.

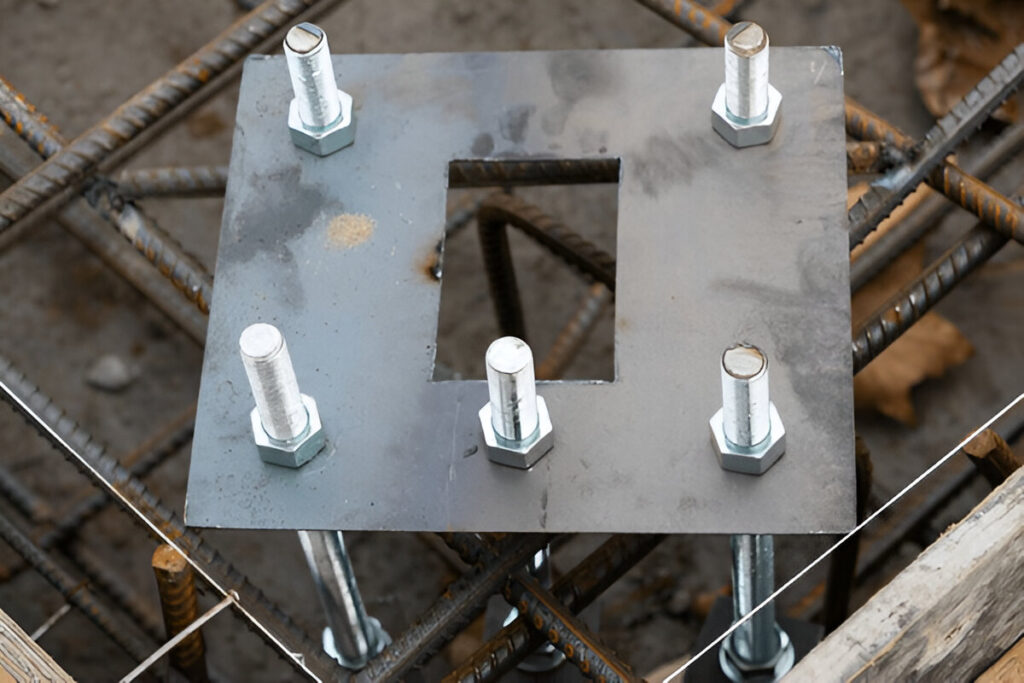

Custom-cut to your specific needs—ensuring the perfect fit for every structural or heavy-duty application

Designed to support standard processing methods, including machining, cutting, and welding—without compromising performance.

Longer-lasting plates reduce maintenance downtime and replacement costs, improving your total ROI.

Alloy steel plates are built to withstand extreme heat without losing strength or shape. In high-temperature environments like pressure vessels and heat exchangers, they resist softening, warping, and fatigue. Thanks to elements like chromium, molybdenum, and nickel, they offer superior creep resistance—making them ideal for steam chambers, thermal reactors, and boiler systems where ordinary steels fail.

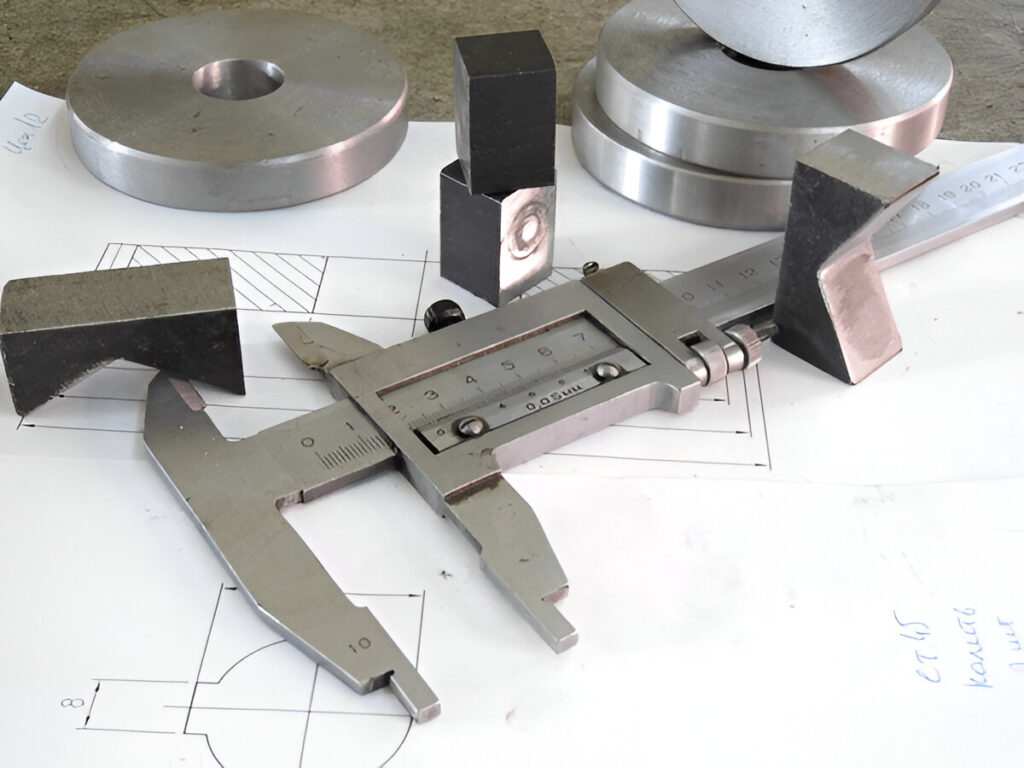

Alloy steel plates demand careful control of cutting speed and feed rate. Lower speeds reduce heat and tool wear, while higher feed rates improve chip removal and efficiency. The result? Cleaner cuts, longer tool life, and precise performance—every time.